Quality and Compliance

Empowering Research and Innovation: Precision, Quality, and Reliability in Every Step

In the manufacturing industry, precision, consistency, and innovation are the cornerstones of success. Our quality management system integrates rigorous raw material assurance protocols with advanced production technologies to uphold the highest standards at every stage.

Explore below for an in-depth overview of the strategies and processes that ensure excellence in every product we deliver.

Building a Resilient Supply Chain: How We Ensure Quality and Reliability

A reliable supply chain is the backbone of manufacturing, and we prioritize its strength. To ensure this, we've adopted a comprehensive strategy of supplier audits, strict quality control, and redundancy planning.

· Supplier Audits and Quality Control:

We conduct regular audits to ensure supplier consistency and material quality. Every batch undergoes rigorous quality checks, backed by full traceability to address any issues swiftly.

· Redundancy Planning:

To prevent disruptions, we maintain at least two backup suppliers for every critical material. This ensures stable production and reliable availability, even during unforeseen challenges.

Optimizing Validation Standards with Our In-House Cell Bank

Our in-house cell bank plays a key role in ensuring rigorous quality standards in cell culture media manufacturing. This resource allows us to validate all raw materials under real-world conditions, confirming their compatibility with cellular growth and functionality.

Validation goes beyond regulatory compliance—it is a critical quality safeguard. By leveraging our cell bank to test every material, we add an extra layer of assurance that our final products meet the high performance standards. While such in-house validation capabilities are rare in the industry, they are an integral part of our commitment to delivering consistently high-quality products.

How We Ensure Consistency and Uniformity in Every Batch

Small inconsistencies in manufacturing can cause significant downstream issues. Our strict weighing standards and advanced mixing technologies ensure precision, uniformity, and reliable product quality.

·Precision Weighing Standards:

We enforce fixed weighing standards across all processes, with equipment regularly calibrated by third-party authorities to eliminate variability and ensure reliability.

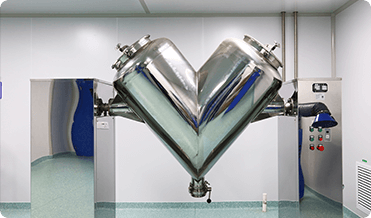

·Advanced Mixing and Milling Technologies:

Uniform blending is essential for products like dry powder media, where inconsistencies can impact performance. To achieve this, we utilize cutting-edge mixers and ball mills, followed by rigorous testing for:

Moisture content to ensure stability

Dissolution clarity for optimal performance

Endotoxin levels to meet stringent quality requirements

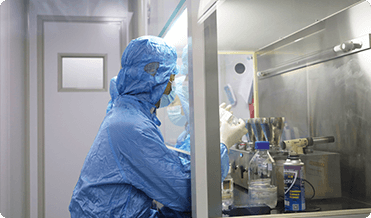

Automated Manufacturing and Certified Facilities: Ensuring Precision and Efficiency

Our facilities feature advanced CIP/SIP (clean-in-place and sterilize-in-place) systems, ensuring consistent and thorough equipment cleaning with minimal human intervention. This reduces variability and enhances cleanliness, a critical factor in maintaining product quality.

This commitment to automation extends to our production lines, where filling, sealing, and labeling are handled with precision and speed.

Our facilities operate under ISO 9001 and ISO 13485 certifications, adhering to strict quality management standards. Cleanliness is maintained at ISO 7 levels in production areas, with localized ISO 5 zones for critical processes. Real-time temperature and humidity monitoring ensures an optimal manufacturing environment, guaranteeing that every product we produce is safe, effective, and consistent. These measures reflect our dedication to delivering excellence at every step of the manufacturing process.

ISO9001

ISO13485

Sterility and Purity Assurance: Delivering Contamination-Free Products

Our protocols include multistage filtration with a 0.1 μm pore size to remove contaminants, followed by gas-tightness testing to ensure flawless filtration system integrity. All liquid reagents are prepared with pharmaceutical-grade Water for Injection (WFI) to meet strict endotoxin standards. Additionally, gamma-ray sterilization is used for reagent bottles to maintain sterility and packaging integrity.

Packaging, Traceability, and Stability Testing

Our ISO 5 cleanroom filling systems, heat-sealed bottles, and secure QR codes linked to Certificates of Analysis (COA) enable customers to verify production history and documentation. For product reliability, we conduct real-time and accelerated stability testing, ensuring consistent shelf life under various storage conditions. Each batch is validated to support optimal cell growth and morphology, with osmotic pressure testing ensuring performance consistency in cell culture systems.

Transportation Validation: Guaranteeing Quality from Factory to Lab

Our products are validated to remain stable at temperatures between -20°C and 45°C for up to two weeks. Continuous temperature monitoring and rigorous packaging stress tests simulate real-world conditions, ensuring sterility and integrity during shipping. These measures guarantee that products arrive ready for use, meeting the quality researchers rely on.

From production to delivery, every step of our process is designed to ensure precision, consistency, and reliability. By combining advanced technologies, stringent quality standards, and comprehensive testing protocols, we are committed to supporting researchers and biomanufacturers with products they can trust. This unwavering dedication to quality and innovation drives our mission to deliver solutions that meet the highest industry expectations, empowering scientific progress and success.